OEM/ODM Factory High Volume Injection Molding - Pole Slack Box – Uni-Moulding

OEM/ODM Factory High Volume Injection Molding - Pole Slack Box – Uni-Moulding Detail:

Pole Slack Box

Export Country:

South Africa

Completion Time:

1 Month

Tag: Plastic Injection Mold

Challange

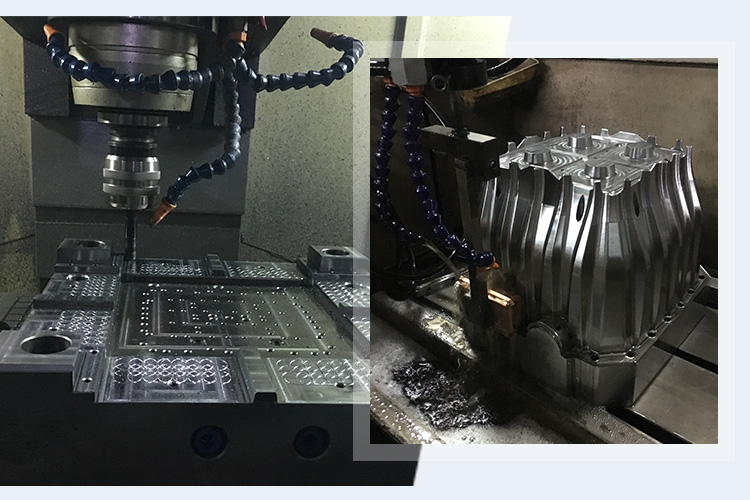

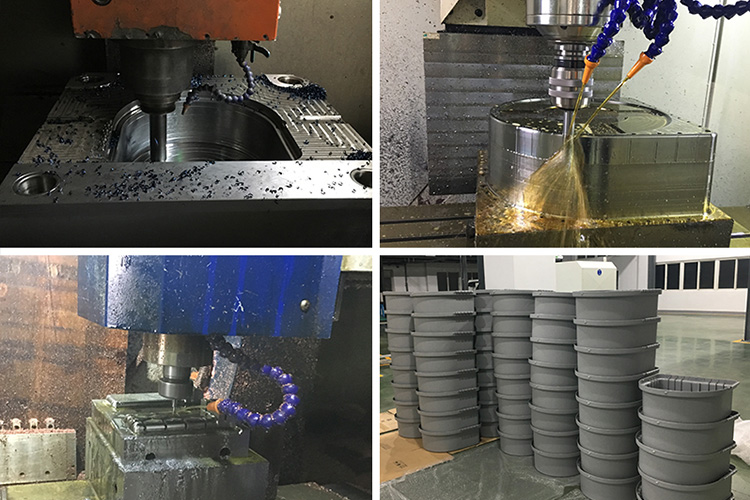

Time schedule: The customer needed it to be finished within 30 days which is not a small mold and with many processes. Especially for so many ribs to be EDM work.

Solutions

Several Machines are working for this tool to finish the job as fast as possible. We made it in time.

Product Application Field

Outdoor power equipment protection box. It mainly prevents the damage of ultraviolet and acid rain to outdoor power equipment and the pollution of power equipment by dust and mixture.

Story

Because the customer used the pole slack box are made of iron. The cost of iron sheet is high, and it is very easy to be corroded by acid rain, resulting in the product life not meeting the expected requirements. The customer once considered using stainless steel material, but after calculating the cost, he considered developing plastic molds and using PP material + UV. Termination cost to a certain extent, and it is firm and durable.

Main Challenges

The cost of iron sheet is high, and it is very easy to be corroded by acid rain, resulting in the product life not meeting the expected requirements. The customer once considered using stainless steel material, but after calculating the cost, he considered developing plastic molds and using PP material + UV. Termination cost to a certain extent, and it is firm and durable.

Because the product is large, the structure belongs to anisotropic structure, and the wall thickness is about 3mm, the conventional design is easy to shrink and deform. Although we have improved the materials, which can reduce certain shrinkage and deformation, the long processing cycle leads to the increase of production cost. Through the efforts of the design and R & D part, we finally reduced the processing time and cost by increasing the size of the gate inlet and adjusting the cooling system and reducing the cooling time and glue injection time.

Main Technology

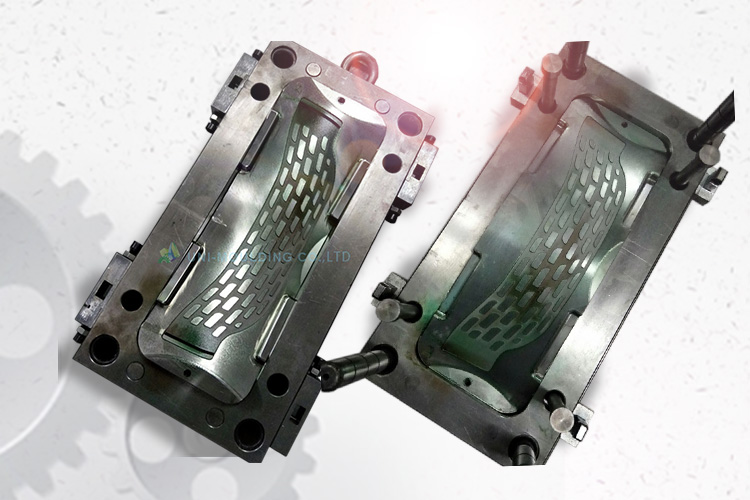

Mold Analysis, CNC Rough Machining, Heat Treating, Finishing Machining, Wire Cutting, EDM, Polishing, Texture.

Mold Details:

Maximum die size: 1100*1000*800mm

Export Area: EU

Delivery time: 45 days

Part Quantity: 5 pcs

Mold Quantity: 4 sets

Number of Processed Sliders: 6 pcs

Mold Material: 718H, NAK80, P20, 718, 45#, etc.

Part Material: PP+UV

Project Leader: Ken Yeo

Product detail pictures:

Related Product Guide:

With dependable high quality approach, great reputation and excellent customer support, the series of products and solutions produced by our firm are exported to lots of countries and regions for OEM/ODM Factory High Volume Injection Molding - Pole Slack Box – Uni-Moulding , The product will supply to all over the world, such as: Libya, San Diego, Kuala Lumpur, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.