OUR COMPANY

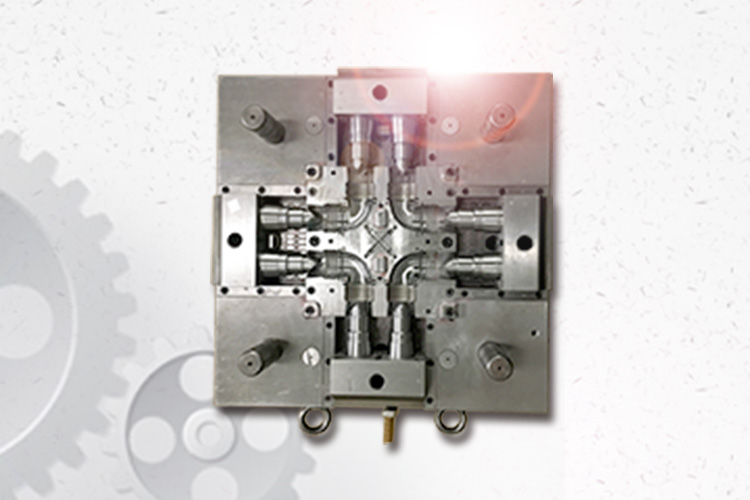

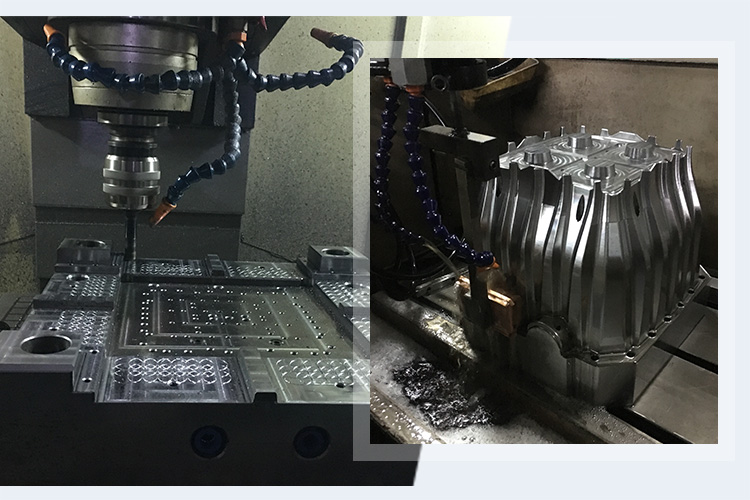

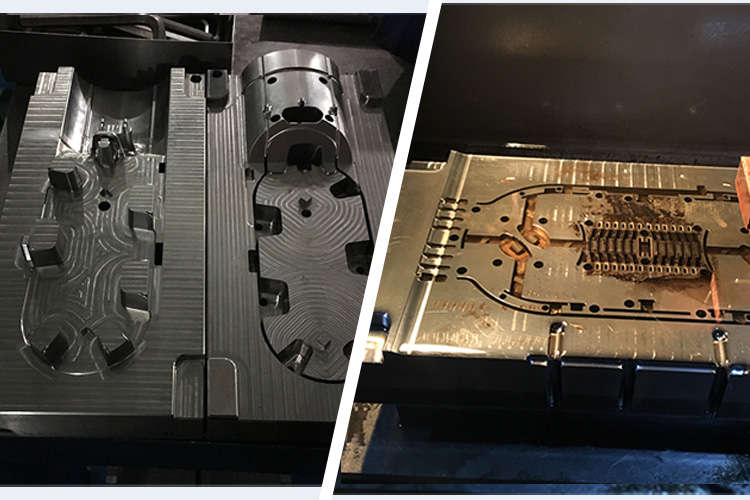

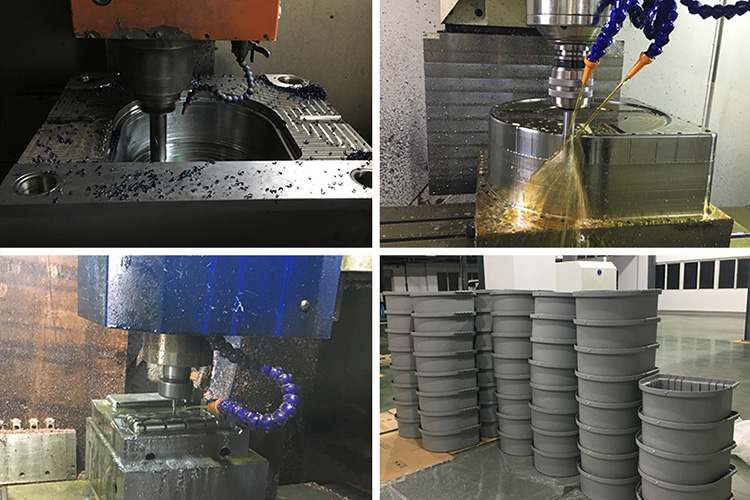

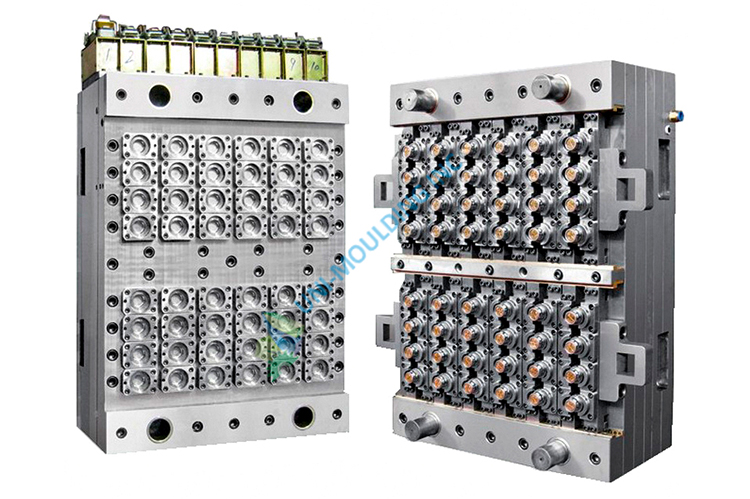

Uni-Moulding is a manufacturer of custom molding for plastic parts, from full design & production management, to produce complete products or components on a regular basis or for one-off requirements.

Our long term clients come from a diverse spectrum of markets, including automotive, healthcare, sports, sanitaryware, home appliances, electronics.

Our expertise encompasses many thermoplastics including PEEK, Nylon, PPO, ABS, PP, Acetal, and some other glassfibre reinforced material. If you require a personalised service from your injection molding company with the backing of years’ experience in the industry, pls contact us and we will be happy to provide you with a quotation or any advice you require.

More About Us

If you need any industrial solution, please contact with us

OUR BEST SERVICES

-

Clean Room Injection Moulding

Read moreFor the time being now, clean room technology is no longer for medical products. Largely dust free ambient conditions have…

-

Project Management & Outsourcing

Read moreProject management: Project management is a key success for manufacturing custom injection molds, it can take 4 to 12 weeks,…

Providing Industrial service with latest technology

and get key to success.

PROJECT CASES

GET A QUOTE

- Phone: +1-708-829-1045(USA) +86-139 5012 8639(CN)

- Email: sales@uni-moulding.com

- US Office: 800 Roosevelt Road Building B Suite 202 Glen Ellyn IL 60137

- Factory 1: NO 191 Siming Industrial Park Tong’an Industrial Zone Xiamen China

- Factory 2: New Mold Town Xinqian Huangyan Taizhou Zhejiang China