Professional Bottle Cap Mold

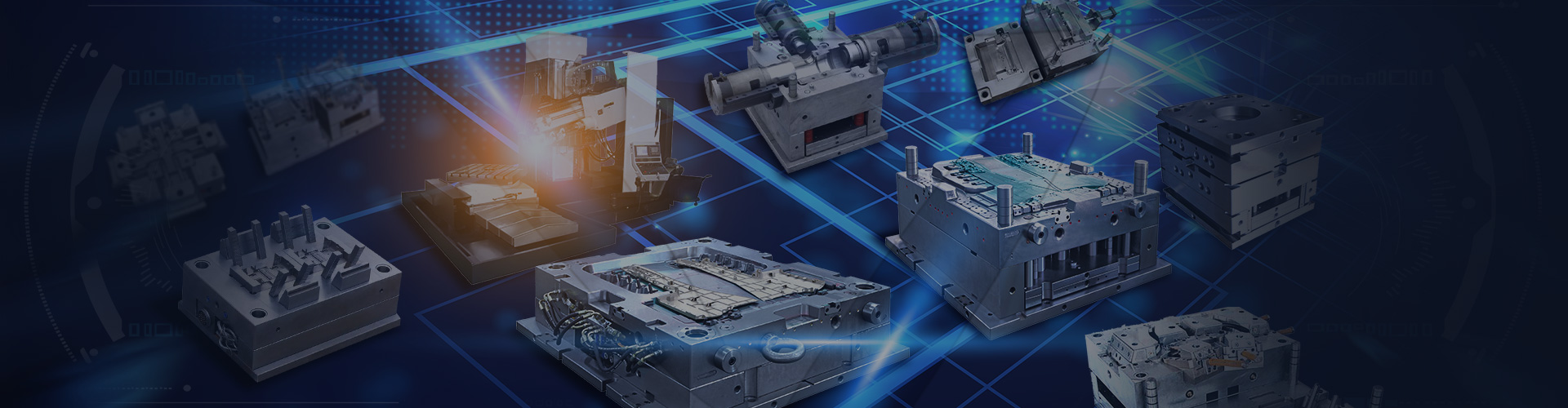

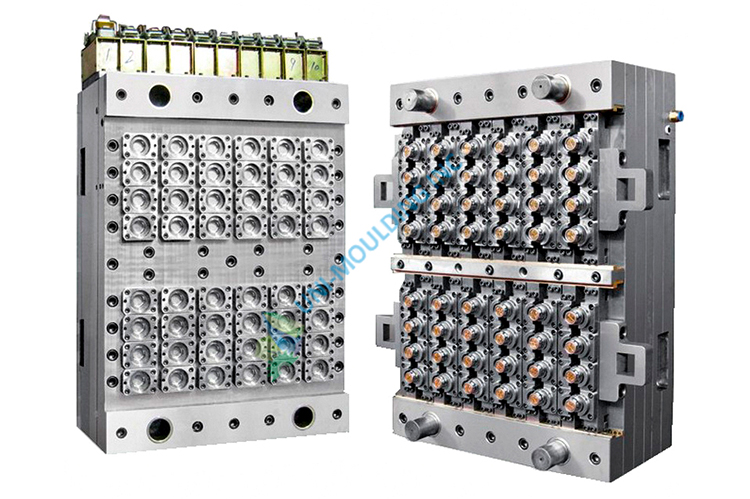

Uni-Moulding specializes in providing various types of bottle cap molds. We have complete R&D team, design department, high-precision processing equipment, quality inspection department and after-sales service team to ensure the excellent quality of each pair of molds. With 15 years of rich experience, we have made many kinds of caps, such as flip-top caps, bow-knot caps, five-gallon caps, cosmetic caps, etc. (up to 128 cavities). Our bottle cap molds have following advantages.

- Mold core and cavity are made of S136 steel after heat treatment to ensure hardness and life.

- Hot runner system with German heating elements accelerates plastic flow in the molten state, saves materials, and ensures product quality stability.

- Use advanced processing equipment to process molds with high precision. In addition, bridge-type three-coordinate measuring instruments and articulated arm measuring instruments are used to precisely control mold size.

- The interchangeable insert saves material costs, and is also convenient for later repairs and maintenance.

- We will provide spare parts, such as core/cavity inserts, and other replaceable mold parts, so that damaged parts can be replaced quickly.

- After mold manufacturing is completed, a series of running inspection tests are carried out in accordance with our company's quality standards.

- We have a professional team of sales engineers, which can customize mold solutions according to your requirements.

- Not only that, we can also build a bottle cap production line-Custom Design Injection Molding Line Set Up. Help you start your production project quickly.